Recycle and Reuse

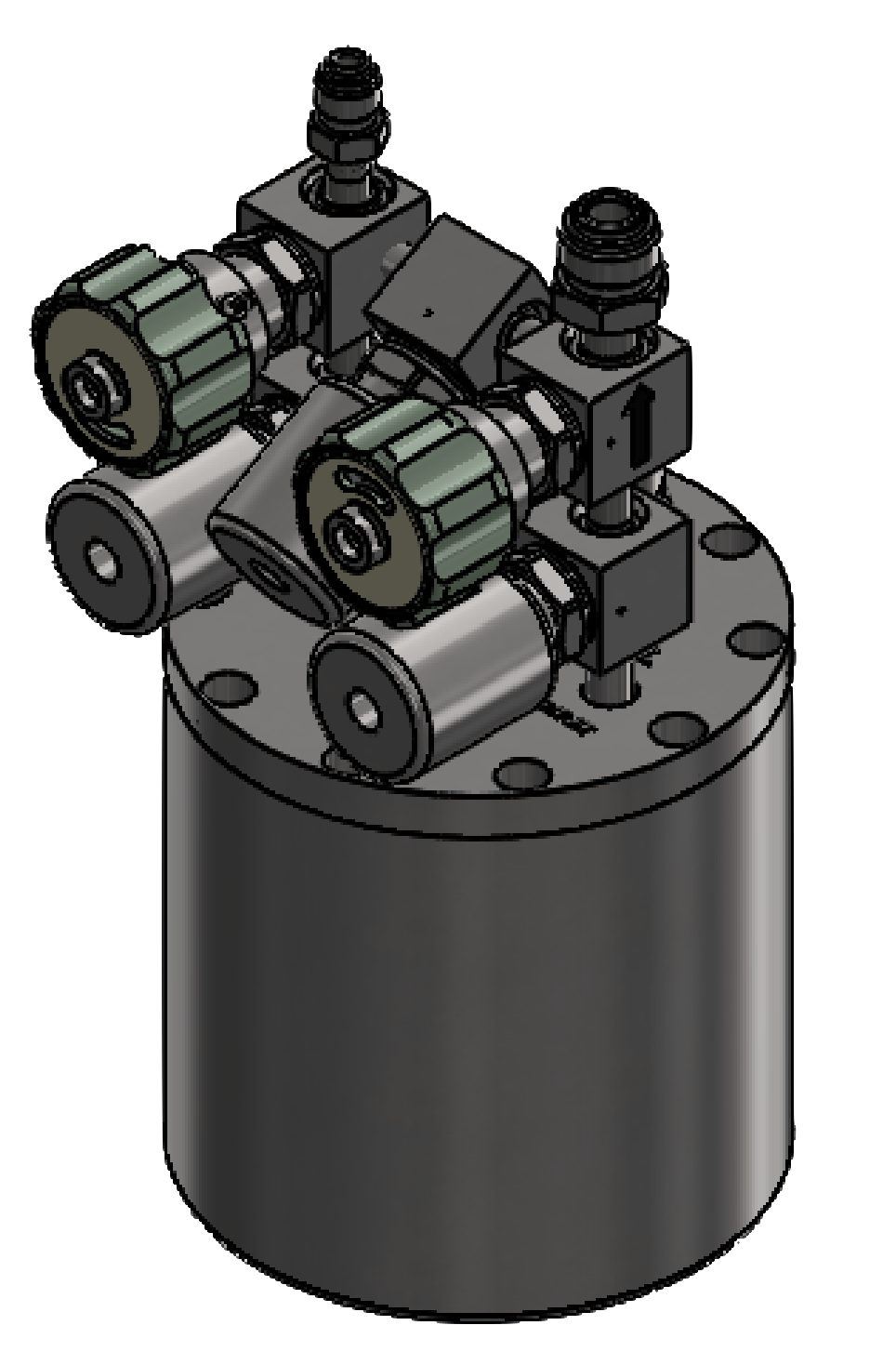

CVD/ALD Ampoule Cleaning Service

At Purity ReSource, we provide high-purity ampoule cleaning services specifically engineered to meet the demands of semiconductor manufacturing. Our eco-friendly, traceable processes are trusted by leading fabs, precursor suppliers, and ALD/CVD tool service providers.

What We Clean

We clean a wide range of chemical ampoules and vessels used for precursors in CVD, ALD, and other high-purity applications. This includes, but is not limited to:

Precursor Materials We Handle:

Metals: Tin, Aluminum, Iron, Cobalt, Nickel, Copper, Zinc, Titanium, Manganese, Ruthenium, Palladium, Indium, Zirconium, Molybdenum, Hafnium, Tantalum, Tungsten, Indium

Rare Earths: Scandium, Yttrium, Lanthanum, Cerium

Semiconductors & Compounds: Silicon, Phosphorus, Selenium, Tellurium, Germanium, Antimony, Iridium, Trimethylaluminum, Hydrazine

Have a new or unusual compound in development? We routinely support R&D teams with custom cleaning protocols and validated methods—contact us to consult.

Cleaning Capabilities & Services

Our full-service ampoule cleaning includes:

✔ Chemical residue removal and neutralization for CVD/ALD precursors

✔ Eco-friendly rinsing with proprietary solutions

✔ Safe, certified disposal of neutralized byproducts

✔ Leak integrity testing

✔ Visual inspections (incoming and outgoing)

✔ Specialized manifold cleaning to preserve valve integrity

✔ DI water fills as required

✔ Full traceability of every unit through our cleaning workflow

Trace Analysis

We offer third-party trace analysis to demonstrate cleanliness.

ICP-MS (37+ metals)

GC-MS

GF-AAS

GC-FID

Each cleaned ampoule includes:

Certificate of Analysis (COA)

Certificate of Conformity (COC)

Lead Time & Volume Discounts

Standard Turnaround: 3–4 weeks

Expedited Cleaning: 1–2 weeks (available for high-volume clients)

Volume Discounts: Offered for batches with identical materials and configurations